Superfinishing is a chip removing machining process. But not one that is comparable to any other. In contrast to the classic lathe turning and grinding methods, there is full surface contact between the tool and the workpiece.

This is precisely the feature that produces the unique characteristics of a perfectly machined surface. This is superfinishing!

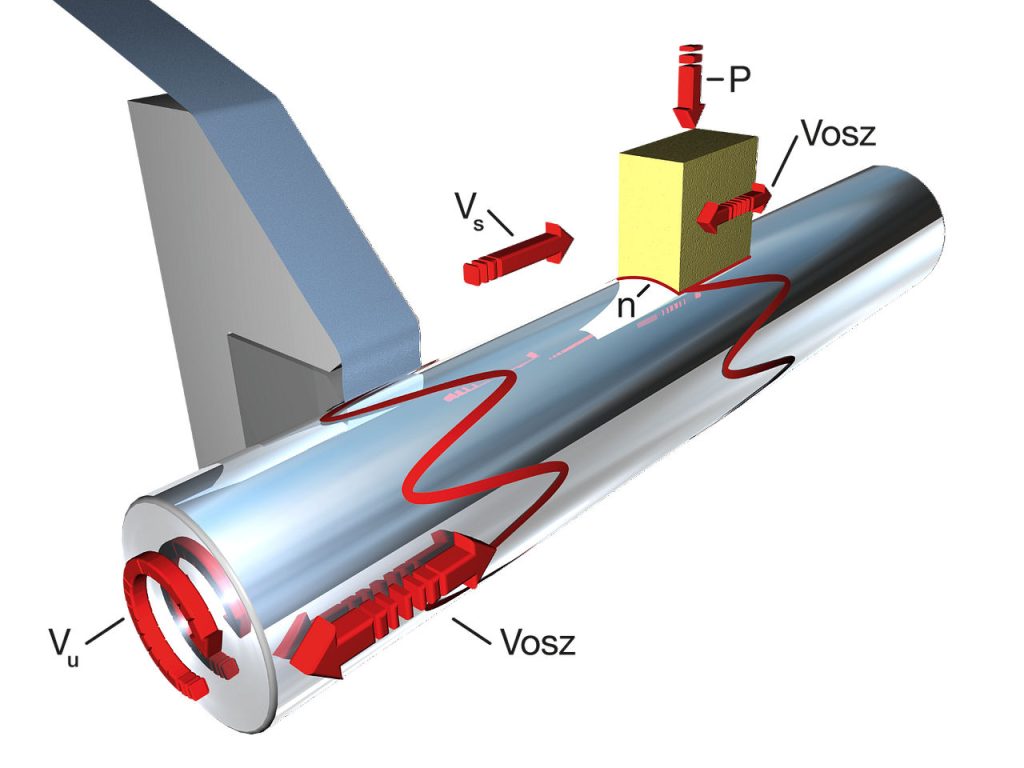

By overlaying workpiece rotation and tool oscillation, each individual grain travels along a sinusoidal line – a feature typical for this process.

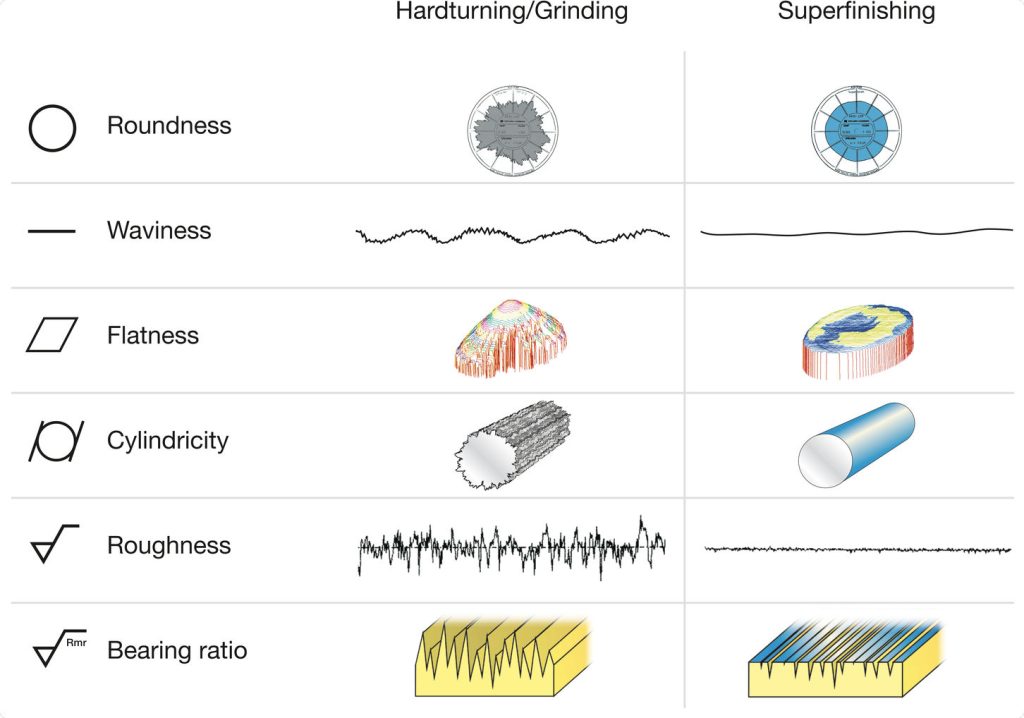

All the grinding grains in contact with the workpiece create a machining pattern by means of overlaying individual sinusoidal lines that cross each other at a particular angle. This generates a specific, defined pattern of grooves and plateaux, which, in turn, results in the particular advantages of the superfinishing process. The grooves act as channels to aid uniform distribution of the lubricant, while the plateaux guarantee a high percentage contact area.

The tools in use here are either bonded grinding compound on a solid substrate, such as ceramic, or on a flexible backing such as a textile tape.Uniform lubricant distribution, higher bearing ratio, improved microgeometry, optimized peak heights – this is workpiece quality made by superfinishing.